-

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

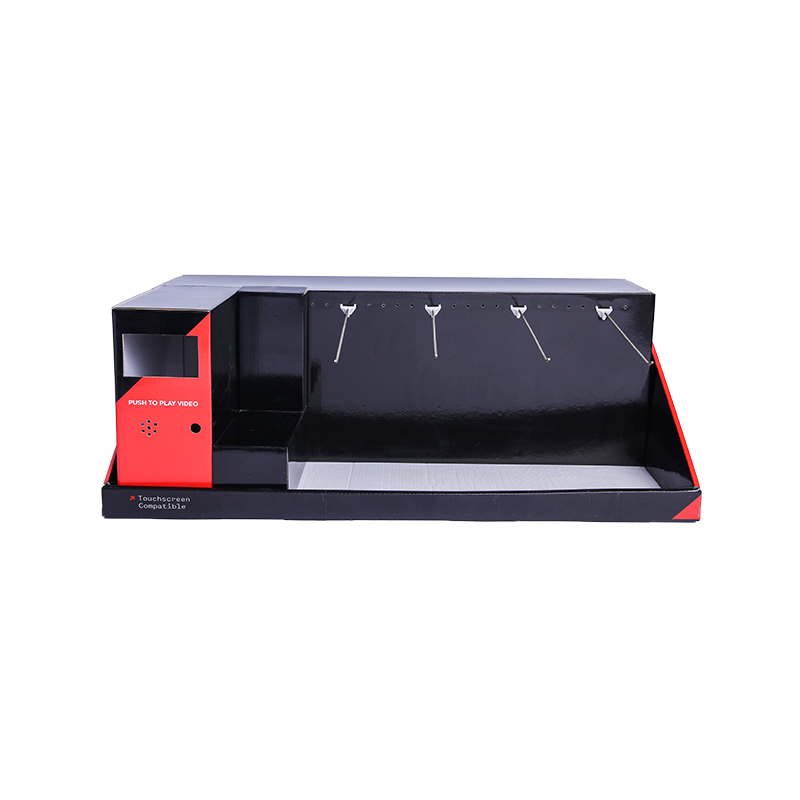

Cardboard display boxes are a vital component of retail packaging, combining structural protection with visual appeal to attract customers and showcase products effectively. One of the key factors influencing the performance and appearance of these boxes is the flute profile of the corrugated cardboard used in their manufacture. Common flute types include E-flute, B-flute, and C-flute, each with unique characteristics that affect durability, print quality, and overall box performance.

Understanding Flute Profiles in Corrugated Cardboard

Corrugated cardboard consists of a fluted corrugated sheet sandwiched between one or two flat linerboards. The flute provides cushioning, rigidity, and thickness to the material. The flute profile is defined by the height and frequency (number of flutes per linear foot), which directly influence the cardboard’s physical properties.

E-flute: Approximately 1.5 millimeters thick, with about 90 flutes per foot. It is the thinnest and finest flute type.

B-flute: Around 3 millimeters thick, with about 47 flutes per foot. It offers a medium thickness and is widely used.

C-flute: Approximately 4 millimeters thick, with about 39 flutes per foot. It is thicker and more robust than B-flute.

Impact on Durability

1. E-Flute Durability

E-flute cardboard is thinner and less bulky than other flutes. Its fine flute structure provides:

Moderate protection: Suitable for lightweight products or display boxes that require a sleek profile.

Lower cushioning: The thin flute offers limited shock absorption, so it is less effective for fragile or heavy items.

Good stacking strength: While it has decent compressive strength for its thickness, it may deform under heavy loads.

Due to its thinness, E-flute boxes are generally less rigid but are ideal when minimal thickness and lightweight packaging are priorities.

2. B-Flute Durability

B-flute offers a balance between thickness and strength:

Improved cushioning: Provides better shock absorption than E-flute, suitable for moderately fragile items.

Higher crush resistance: Its thickness and flute height improve box rigidity and durability.

Good printability support: The smoother surface compared to C-flute helps maintain durability without sacrificing print quality.

B-flute is commonly used for retail display boxes needing a balance of protection and presentation.

3. C-Flute Durability

C-flute is thicker and stronger, offering:

Superior cushioning: The thick flute acts as a strong shock absorber, protecting fragile or heavy products.

High stacking and crush resistance: Suitable for bulkier, heavier items and for displays subjected to rough handling.

Increased bulk: The thicker profile adds volume, which might increase shipping costs.

C-flute is preferred when maximum durability and protection are required, especially in industrial or heavy-duty retail displays.

Impact on Aesthetic Quality

1. E-Flute Aesthetic Quality

Smooth surface: The thin, fine flutes provide a smooth and flat printing surface.

High-resolution printing: Ideal for detailed graphics, logos, and photographic images.

Premium look and feel: The sleek profile allows for sophisticated packaging designs with high-end finishes.

Less visible flute texture: Minimal corrugation visibility enhances visual appeal.

E-flute is excellent for products requiring elegant, high-quality visual presentation.

2. B-Flute Aesthetic Quality

Moderate surface smoothness: B-flute has a slightly more textured surface than E-flute but still supports high-quality printing.

Good balance of print quality and strength: Allows for vibrant colors and detailed graphics with reasonable durability.

Flute visibility: Slight texture may be visible under certain lighting or finishes, adding subtle depth.

B-flute offers versatility for a wide range of retail packaging applications, balancing aesthetics and functionality.

3. C-Flute Aesthetic Quality

More textured surface: The thicker flute creates a more pronounced texture, which can affect print sharpness.

Reduced print resolution: Fine details may be less clear compared to E- or B-flute surfaces.

Rustic or rugged look: The texture can convey a natural or eco-friendly image, depending on branding.

Requires heavier liners for high-quality printing: To improve printability, thicker linerboards are often paired with C-flute.

C-flute is best suited for packaging where ruggedness or natural appeal is emphasized over fine graphic details.

Additional Considerations

Printing Method Compatibility: E-flute’s smooth surface is compatible with a wider range of printing methods such as digital, offset, and flexographic printing, allowing greater design flexibility.

Box Weight and Shipping Costs: Thicker flutes add weight and volume, which can increase shipping expenses.

Environmental Impact: Thinner flutes use less material, which may reduce environmental footprint and improve recyclability.

Choosing the appropriate flute profile for cardboard display boxes depends on the desired balance between durability and aesthetic quality:

E-flute is ideal for lightweight, visually premium packaging requiring fine print detail but moderate protection.

B-flute offers a versatile balance suitable for most retail display applications needing good durability and visual appeal.

C-flute excels in protection and strength for heavier or fragile products but offers a more textured surface that may limit print resolution.

Understanding the properties and trade-offs of each flute type enables manufacturers and designers to tailor cardboard display boxes that meet both functional requirements and branding goals effectively.

Annhiu Address: Yishan Road and Qingshengou Road Intersection, Suzhou Economic Development Zone, Anhui, China

Tel: +86-0557-3781111

E-mail: [email protected]

Hangzhou Address: Building 3, No.286, Renliang Road, Renhe Street, Yuhang District, Hangzhou, Zhejiang, China

Tel: +86-0571-56396277

E-mail: [email protected]

Copyright © Hangzhou Shengpin Packaging Co., Ltd. All Rights Reserved.