-

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

+86-0557-3781111 / +86-0571-56396277

Drinks packaging boxes are a critical component in the global beverage supply chain, fulfilling multifaceted roles that extend well beyond mere containment. They are engineered to provide optimal protection, enhance brand identity, ensure compliance with regulatory standards, and increasingly address sustainability challenges faced by the packaging industry. This article explores the advanced materials, innovative design strategies, and environmental considerations shaping modern drinks packaging boxes.

Materials Science and Structural Engineering

The core function of drinks packaging boxes is to protect liquid containers—whether glass bottles, aluminum cans, or cartons—throughout handling, transportation, and storage. Corrugated fiberboard remains the dominant substrate due to its excellent strength-to-weight ratio, cushioning capabilities, and cost efficiency. The choice of flute profile (A, B, C, E, F) within corrugated board structures is critical for balancing compressive strength and cushioning performance based on the specific beverage type and supply chain stresses.

Recent advancements in paperboard laminations, including water-based barrier coatings and polymer films, have significantly enhanced moisture resistance and oxygen barrier properties. These coatings prevent degradation of both the packaging material and the beverage, extending shelf life while maintaining recyclability. Nanocomposite additives are also being researched to improve mechanical strength and antimicrobial activity within packaging substrates.

Design Innovations for Functionality and Brand Differentiation

The structural design of drinks packaging boxes is evolving rapidly to address user convenience and shelf impact. Ergonomic features such as integrated carrying handles, quick-open perforations, and resealable closures enhance consumer usability. Modular designs that facilitate stacking and palletization improve logistics efficiency and reduce distribution costs.

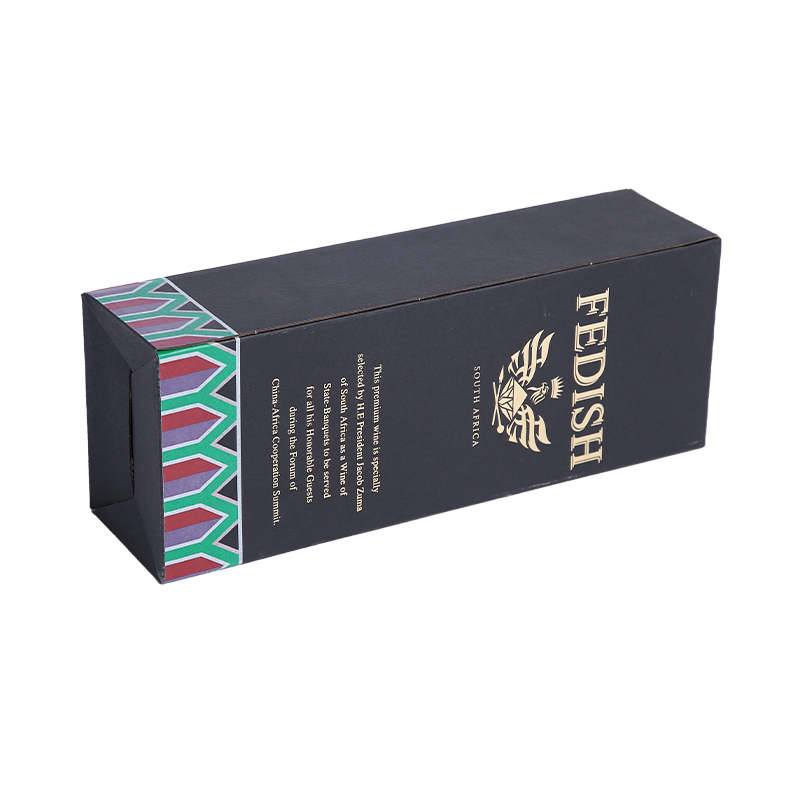

From a marketing perspective, packaging serves as a powerful communication tool. Techniques such as high-definition digital printing, embossing, debossing, and metallic foil stamping provide tactile and visual appeal. Custom die-cut windows showcase product aesthetics, while augmented reality (AR) and QR code integrations enable interactive consumer engagement, connecting physical packaging with digital content.

Sustainability and Regulatory Compliance

Environmental sustainability has become a primary driver in drinks packaging development. The shift toward renewable, biodegradable, and recyclable materials is paramount. Innovations include the use of recycled fibers with enhanced mechanical properties, water-based inks, and adhesive formulations optimized for recycling processes.

Many beverage companies are adopting circular economy principles by designing packaging for reuse or refill systems, thereby reducing single-use packaging waste. Regulatory frameworks globally are also tightening, mandating greater transparency in material sourcing and waste management, as well as imposing restrictions on hazardous substances.

Lifecycle assessment (LCA) tools are increasingly utilized to quantify the environmental footprint of packaging options, enabling data-driven decisions that balance performance with ecological impact.

Industry Trends and Future Outlook

The drinks packaging box industry is witnessing rapid integration of smart packaging technologies. Sensors embedded within packaging can monitor temperature, humidity, and freshness, providing real-time data to consumers and supply chain stakeholders. This technology promises to reduce spoilage and enhance product safety.

Additionally, advances in biodegradable composites and plant-based polymers offer promising alternatives to traditional plastics, although challenges remain in scalability and cost competitiveness.

Drinks packaging boxes represent a convergence of material science, engineering design, sustainability imperatives, and brand strategy. Continued innovation in these areas will be crucial to meet evolving consumer expectations, regulatory demands, and environmental goals, ultimately shaping the future of beverage packaging worldwide.

Annhiu Address: Yishan Road and Qingshengou Road Intersection, Suzhou Economic Development Zone, Anhui, China

Tel: +86-0557-3781111

E-mail: [email protected]

Hangzhou Address: Building 3, No.286, Renliang Road, Renhe Street, Yuhang District, Hangzhou, Zhejiang, China

Tel: +86-0571-56396277

E-mail: [email protected]

Copyright © Hangzhou Shengpin Packaging Co., Ltd. All Rights Reserved.